An iconic Australian dairy company were after a solution for transferring their viscous, abrasive and sensitive product. Ease of maintenance, including frequent wash-downs, were all to be factored into the solution.

This company produces approximately 80,000 tonnes of product per annum, and employs a team of top engineers and scientists, who are continually working on their state-of-the-art equipment and processes to deliver top quality product. So as not to let the company lose their reputation, a suitable solution that worked was essential.

Due to Allflo providing multiple solutions to this company, our expertise was once again relied upon, and we became the first company of choice.

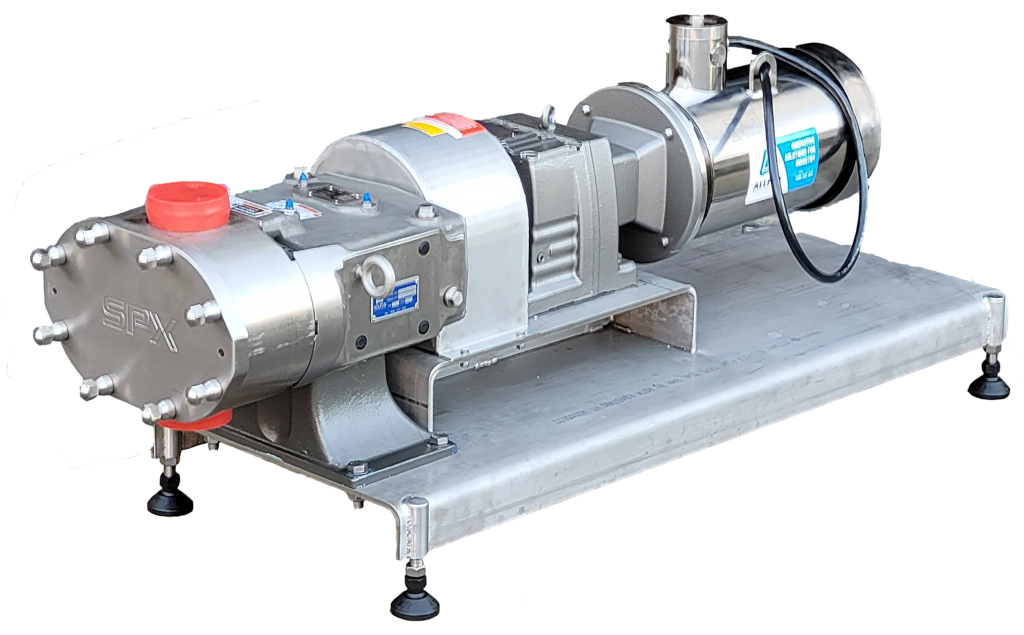

After a few discussions with the maintenance team at this company; Allflo’s technical team came up with a solution meeting all their needs. The solution involved supplying the company with a new generation Waukeska U3 Positive Displacement Pump, boasting multiple beneficial features, on a specially designed and manufactured base.

This custom base meant that:

- the common build-up points were removed, therefore contributing to an easier cleaning routine

- it was made higher than the usual base for ease of transportation around the plant, and making regular maintenance routines more efficient

The company has significantly improved production performance and improved maintenance safety, making this line of product a whole lot more efficient.

Sometimes global leading companies can become stuck with ways to solve their pumping complications, but Allflo has a team with over 70 years of experience and expertise, passed down the generations.

So, it’s always worth a call or a message to see what the Allflo team can bring to the table for your next pumping difficulty.