Seal Support Systems

Back-to-back seal arrangement with barrier fluid

This arrangement has two shaft seals mounted in opposite directions. Between the two seals is a pressurised barrier fluid. The barrier fluid has several advantages to the product-side seal as compared to a single shaft seal:

- Compensates leakage

- Indicates the pressure in the barrier fluid with possible alarm

- Indicates when the barrier fluid level is low/high with possible alarm

- Allows refill of barrier fluid with pressure maintained in the seal cavity

- Constant air pressure secures the barrier fluid pressure

This seal arrangement is suitable for poisonous and explosive liquids when no leakage from the pumped medium to the atmosphere can be accepted. The barrier fluid pressure is higher than the pump pressure, as a result of which any leakage will pass from the barrier fluid to the pumped medium. The barrier fluid pressure must be minimum 2 bar or 10 % above the pump medium pressure close to the seal. As the clean barrier fluid has a higher pressure, it also serves as lubricating liquid for all seal faces. The back-to-back shaft seal arrangement is particularly suitable for sticky media and/or liquids with many abrasive particles. The seal arrangement prevents the pumped medium from entering the seal gap and consequently prevents excessive wear. Water or water mixed with glycerine is the most common liquid in closed pressurized back-to-back arrangements because it is non-poisonous and compatible with many types of pumped media. The barrier fluid chosen must always be compatible with the pumped medium. This solution is mainly used in dead-end applications where cooling from the seal chamber is sufficient.

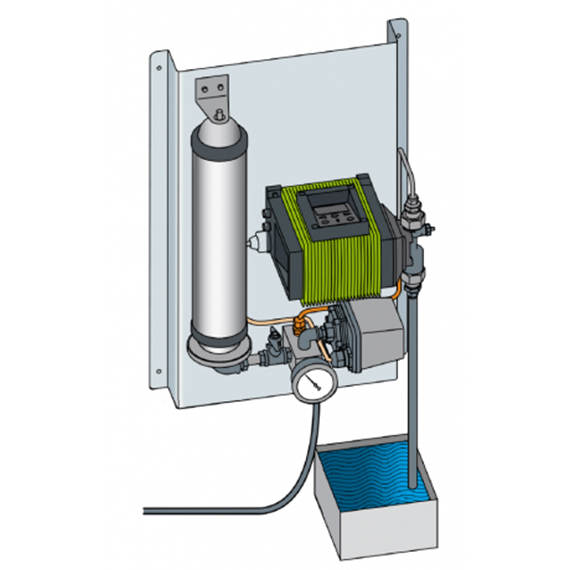

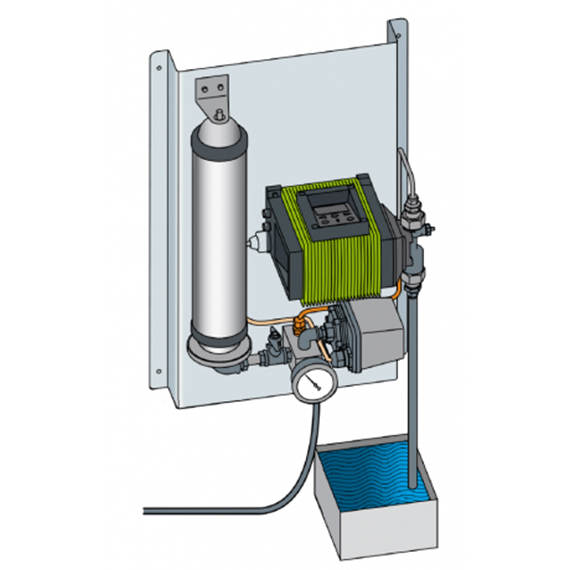

Seal Support System 900274

The overpressure in the barrier fluid in relation to the pumped medium pressure, is by means of Seal Support System 900274. This includes an auxiliary pump which automatically keeps the level set for the overpressure. The set point of the barrier liquid pressure is set by means of pressure switch. When the pressure drops below the set point, the dosing pump will start and thus maintain a higher pressure in the seal chamber. Barrier liquid is supplied from reservoir. One Seal Support System 900274 can supply several pumps with back-to-back seal arrangements.

Note: Connecting pipes/hoses are not included.

Allflo is experienced in providing innovative solutions to industry, so if you need further information or would like to speak to our team regarding your application, call 1800 333 424 or simply fill out the online enquiry form for a prompt reply.